With expanding consciousness about environmental sustainability, industries are analyzing the environmental footprint in their functions, and CNC milling is no exception.

Downtime Reduction: Changing a cutting Device just just before it fails assists steer clear of catastrophic machine crashes.

This text explores the profound advantages of AI in CNC machining, supported by crucial details and studies that underscore the transformative potential of this technology.

AI don't just simplifies programming jobs and also improves precision in creation. This transformation is largely because of AI's power to quickly assess knowledge and identify exceptional paths working with Superior algorithms.

The fabric dealing with industry takes advantage of conveyors in order that products are dispersed successfully, AC or DC motors are chosen dependant upon the pounds it has to carry as well as the pace at which it should work.

This proactive technique identifies prospective issues before they effect the final solution and enhances In general product quality. This technology underscores their commitment to advancing producing excellence and customer pleasure as a result of progressive AI applications.

Plane Components: CNC lathes are used to supply various plane parts like turbine blades, landing equipment components, and structural parts.

Some CNC machines that Mix types of machining, fabrication, 3D printing, welding, plus more for precise purposes. Used CNC are capable of making quite complicated parts and assemblies with specific tolerances and excellent repeatability.

Amongst the largest advantages of AI in CNC machining is predictive routine maintenance. Usually, servicing is scheduled at regular intervals, if the machine requires it or not. But with AI, we can easily predict whenever a machine is likely to are unsuccessful, dependant on its running conditions and historic data. This means we are able Next to deal with things in advance of it breaks, reducing downtime and preserving money.Sensors over the machinery acquire information on things such as temperature, vibration, and sound. This details is then fed into an AI algorithm that looks for patterns and anomalies.

The combination of AI into CNC machining is a lot more than a development; it’s a paradigm change. Individuals who embrace this revolution will guide the way in innovation, efficiency, and high quality, placing new requirements for your industry worldwide.

Nicely-maintained used machine tools can offer many years, and lots of cycles of use. CNC machines could be upgraded, rebuilt, have controllers replaced and connected for remote checking. Rather than buying a new CNC, manufacturers get all the features and dependability by diligently selecting CNC equipment with a trusted associate.

The complexity of your parts that could be manufactured on these 3-axis turning centers is pushed because of the Dwell tooling capabilities plus the amount of tooling slots about the turret.

Once you've determined your use situations, it's time to pilot and iterate. This means starting small, tests your AI Alternative, Mastering from the final results, and iterating determined by Whatever you've realized.A good way To achieve this will be to Stick to the lean startup methodology. This can be a method of producing businesses and merchandise, which aims to shorten merchandise advancement cycles and swiftly uncover if a proposed business product is feasible.

Machining is among A very powerful production processes. Machining is very complex system. Recently, modeling approaches employing neural network have captivated awareness of practitioners and researchers. The training skill of nonlinear romance within a cutting operation without likely deep to the mathematical complexity makes neural community a pretty different choice for many researchers to design cutting processes This technique offers a cost effective alternative in modeling of machining procedure.

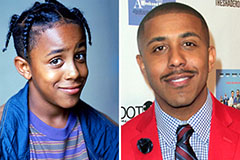

Marques Houston Then & Now!

Marques Houston Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! Batista Then & Now!

Batista Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!